The Craftsman LT2000 drive belt diagram provides basic information on the belt and how it works. It is important to keep the riding lawn mower belt in good condition so that it can provide proper operation of the machine. The diagram also provides information on when the belt should be replaced.

A belt is what helps spin the blades and cut the grass, so it’s important to have a good, sturdy one. And if it breaks or malfunctions in any way, you’re going to have trouble getting your lawn looking nice again.

Fortunately, drive belts are pretty easy to replace on most of riding mowers. All you need is a wrench, screwdriver, and replacement belt. The process usually only takes a few minutes and is relatively simple. However, if you’re not comfortable doing it yourself, take it to a professional.

So, today we are covering everything about the Craftsman lt2000 drive belt diagram. How it works how to replace it, why it’s important, and more.

Let’s dig into dipper.

The Craftsman LT2000 Drive Belt Diagram

The Craftsman LT2000 is a great lawn mower for the homeowner who wants an easy to operate and reliable machine. One of the things that can make this machine difficult to work on is the drive belt. This belt can become damaged over time, and if it is not replaced, the machine will not operate properly.

Let’s sort all the topics in succession, to start with the drive-belt demonstration.

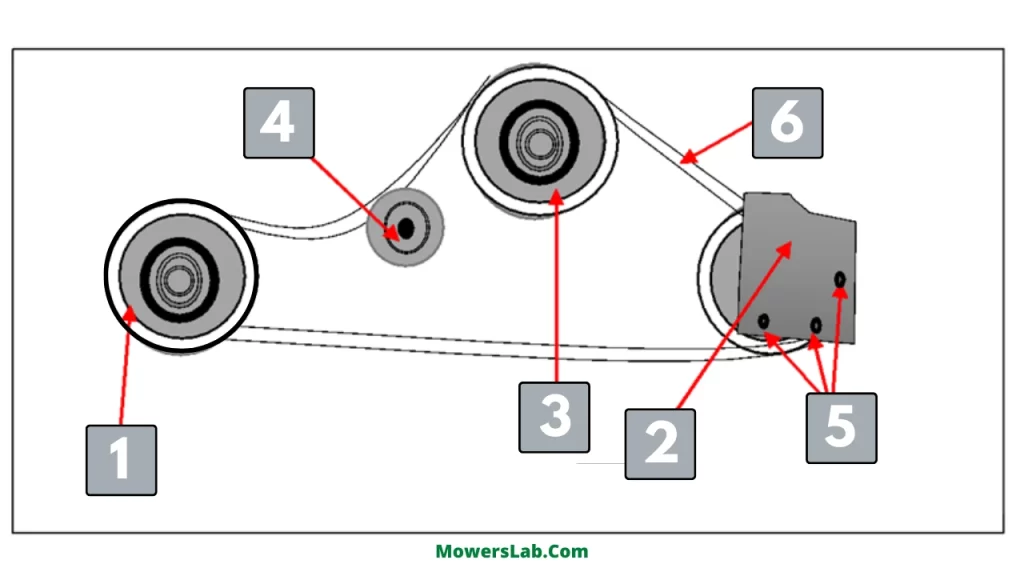

Here, you will find more detail about the components we have numbered in the Craftsman LT2000 drive belt diagram shown earlier.

| Moving Parts | How does It work? |

|---|---|

| Left Hand Double Pulley | Move heavy loads with less effort |

| Right Hand Double Pulley | Move heavy loads with less effort |

| Center Pulley | Help to hold drive belt |

| Deck Idler Pulley | Maintaining tension on the drive belt |

| Self-Tapping Screw Assembly | Types of fasteners |

| Deck Belt | It connects the engine |

Left Hand Double Pulley

The left-hand double pulley is a great way to move heavy loads with less effort. This is because there is less effort necessary for moving the load.

And it happens due to the double pulling helping in increasing the overall mechanical advantage.

Right Hand Double Pulley

The right-hand double pulley on a lawn mower is located on the right side of the machine and serves the same purpose as the left-hand double pulley.

Center Pulley

This is the craftsman LT2000 drive belt pulley located in the center. To hold a rope wire rope or belt there can be a grooved wheel. This sheave or pulley helps to guide and support whatever needs to be transported.

The pulley can be found on many different machines and tools, making it a very versatile piece of equipment.

Deck Idler Pulley

The deck idler pulley is responsible for maintaining tension on the drive belt and guiding it around the engine. The belt needs to be tight so that it can efficiently power the engine.

If there is too much slack in the belt, it can slip off the pulleys or cause the engine to overheat. The idler pulley also helps to keep the belt aligned properly so that it doesn’t rub against any of the other components.

Self-Tapping Screw Assembly

There are certain types of fasteners that can laterally drill on their own while being screwed to materials that can be metal, plastic, or wood.

These screws are called self-tapping screws and they have a special design that allows them to create their own hole as they’re being inserted into the material. This makes them ideal for use in a variety of applications, including metal, plastic, and woodworking.

Deck Belt

The deck belt is a key part of the riding lawn mower. It is what connects the engine to the blades, and it needs to be in good condition in order for the lawn mower to work properly. If the deck belt is worn or damaged, it can cause the engine to overheat or the blades to become misaligned. In some cases, it can even cause the engine to fail.

That’s why it’s important to make sure that your deck belt is in good condition and replace it if necessary. A new deck belt should be a compulsory element of every riding lawn mower. It’s an inexpensive way to ensure that your lawn mower will run safely and efficiently.

Craftsman LT2000 Drive Belt Size

The Craftsman LT2000 riding lawn mower is best suited with the Rinlius 144959 Deck Belt, measuring 1/2 inch in width and 95 inches in length. This specific belt is designed to work seamlessly with the LT2000 model, ensuring that the mower’s deck operates efficiently.

By installing the Rinlius 144959 Deck Belt in the recommended size, you can ensure that your lawn mower performs at its best when tackling your lawn mowing tasks.

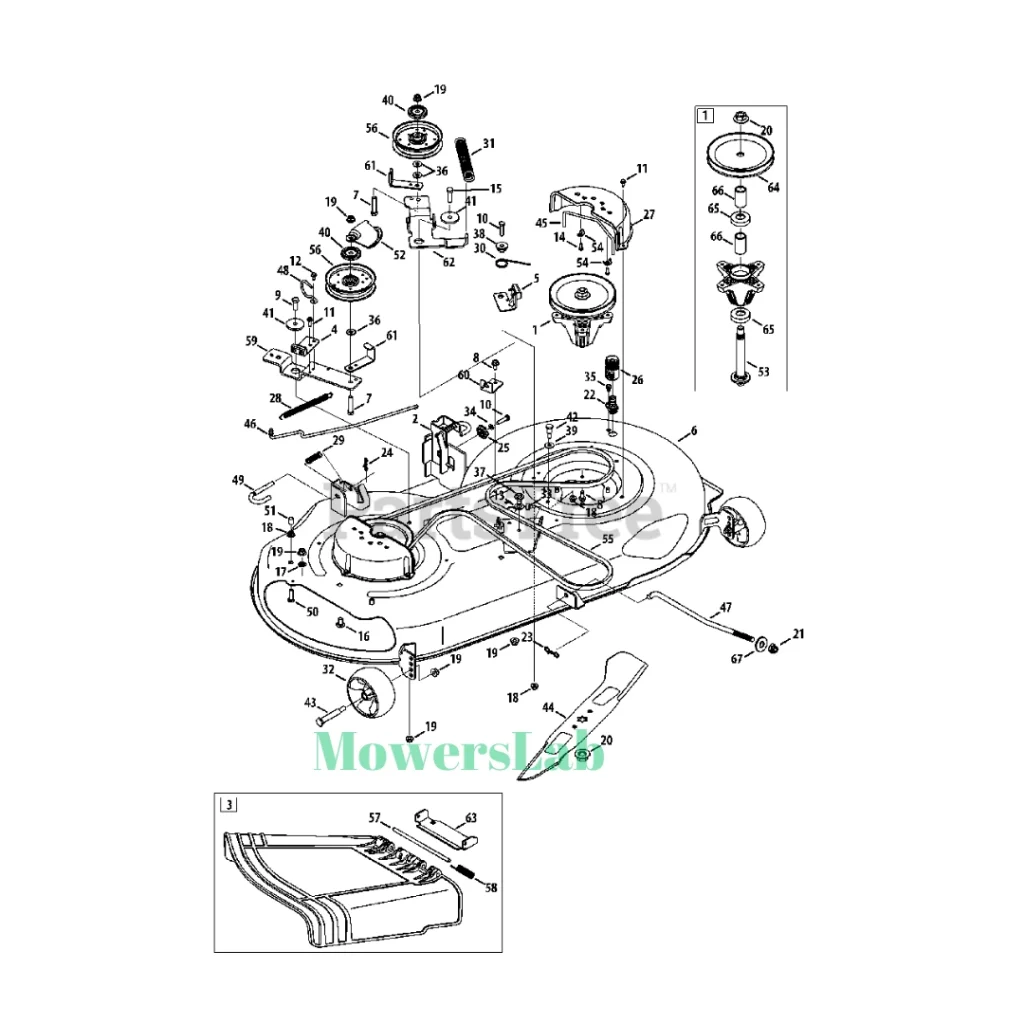

Here’s the full image of this mower deck diagram:

Craftsman LT2000 Drive Belt Working Mechanism

The drive belt is a crucial part of the Craftsman LT2000 lawn mower. The most prominent job of the drive belt is ensuring that there is power transferred to all the parts of the mower. This includes the engine, blades, and wheels. The drive belt also helps to create radial torque with the engine shaft. This helps to ensure that the blades are able to spin at a high velocity, which in turn results in a clean-cut lawn.

Also, the torque will be able to allow the engine to operate. If the whole performance continues to run to and from work, there will be a link to turning the mower head as well as turning the propeller.

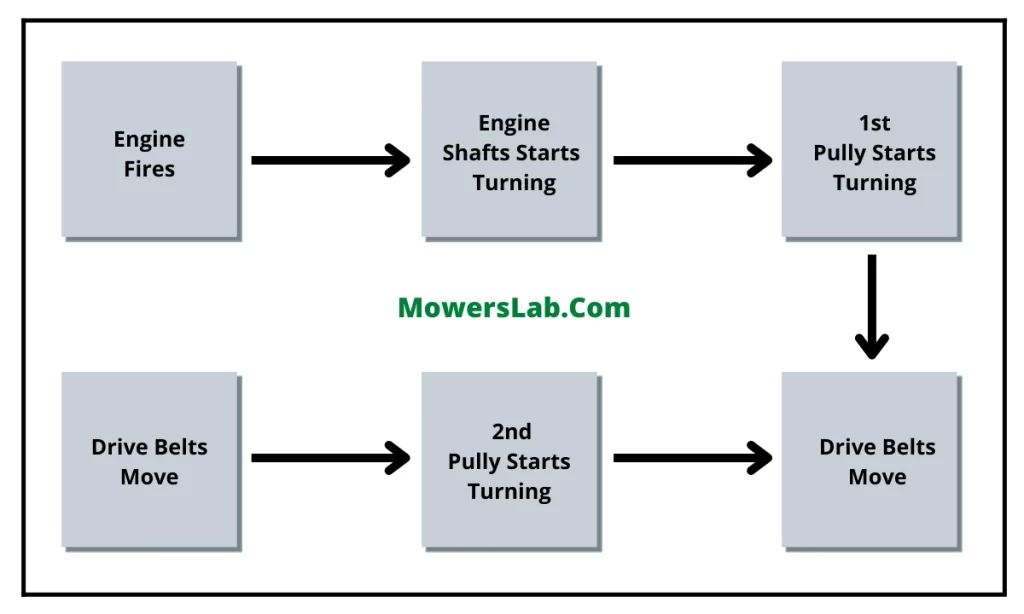

How Can Craftsman LT2000 Drive Belt Transfer Power?

There are many people who are confused about how the drive belt on a Craftsman LT2000 can transfer power from the engine to the transmission. Some people think that the belt is just there for show and that it doesn’t do anything to help power the mower. But this is not the case – the belt actually plays a very important role in getting power from the engine to the wheels.

The drive belt on a Craftsman LT2000 is connected to both the engine and the transmission. When the engine turns, it causes the belt to spin, which in turn spins the transmission. This is what allows power to be transferred from the engine to the wheels, allowing the mower to move.

It’s important to understand how this works if you want your Craftsman LT2000 to run properly.

Initially, the first pulley enables the movement of the drive belt, and the drive belt then causes the second pulley to move as well. The 2nd pulley remains connected to the input shaft when it’s moved to lead the transmission shaft as well.

Overall, the pattern becomes complete like that. Thus, the entire movement pattern becomes complete.

Here’s a Demonstration of What Happens on Craftsman Lt2000 Drive Belt

After a power line entered the shaft, it transferred to both the blades’ drive wheels. This lets the blades move back and forth in a circular motion. As a result, this mimicked how the engine’s drive belt helped the mower to turn back and forth.

How to Replace Craftsman Lt2000 Drive Belt?

Replacing the Craftsman LT2000 drive belt is an easy task that can be done by anyone with a few tools and some experience. If your belt has broken, or if it’s time for a replacement, following these steps will help get you back in business quickly.

How to Remove Craftsman Lt2000 Drive Belt

- Read the mower manual 1st. You can easily find “Remove Mower” in the section of the manual guide,

- Pull the belt off the stationary idler (A) and clutch idler (B).

- Pull off the belt form centerspan idler (C).

- Pull belt slack to the back, lifting it gently upward from the transmission input pulley and from there above the cooling fan blades (D).

- Remove the belt from the pulley at the rear of the vehicle (E).

- Pull the belt to the rear of the tractor, pulling the steering plate (F). Remove it from the top of the tractor.

How To Remove Craftsman LT2000 Drive Belt

- 1st we recommend seeing the manual. You can find “INSTALL MOWER” in this section of the manual.

- Install a new belt behind the front axle to the cutter bar (F) and over the clutch pedal shaft (G).

- Pull the belt toward the front of the tractor and roll over the belt onto the engine pulley (E).

- Pull the belt back towards the rear of the tractor until it stops near the transmission cooling fan and the input pulley (D). Be sure the belt is wrapped in the belt holder.

- Install a belt on the center of the center span of the idler (C).

- Install the belt, using the stationary idler (A) and gripping idler (B).

- Carefully make sure that the belt is entirely inside all pulleys and inside all belt guides and keepers.

With this step-by-step breakdown hopefully say, you can easily replace the Craftsman LT2000 Drive Belt

How to Install Craftsman LT2000 Drive Belt

- Safety First: Ensure the mower is turned off and the spark plug wire is disconnected to prevent accidental starting.

- Lift the Mower Deck: Raise the mower deck to its highest position. This can usually be done by adjusting the deck height lever, typically located on the side of the mower.

- Locate the Drive Belt: Find the existing drive belt. It’s the belt that connects the engine’s pulley to the transmission pulley. You may need to remove the mower deck for better access.

- Remove the Old Belt: Carefully release the tension on the old drive belt, usually done by disengaging the belt tensioning idler pulley. Slide the old belt off the pulleys. Take note of the belt’s routing for reference during installation.

- Prepare the New Belt: Ensure you have the correct replacement drive belt, preferably one designed for your Craftsman LT2000 model. Check the belt’s condition for any defects before installation.

- Thread the New Belt: Starting at the engine pulley, carefully thread the new drive belt around all the pulleys according to the routing diagram you noted earlier. Make sure it’s properly seated in all the pulley grooves.

- Tension the Belt: Re-engage the belt tensioning idler pulley to apply tension to the new belt. This will help ensure proper operation. Make sure the belt is snug on all pulleys.

- Test Operation: Manually spin any pulleys or belt tensioners to verify that the belt is correctly seated and there are no twists or misalignments.

- Reassemble the Mower Deck: If you removed the mower deck, reattach it carefully, ensuring the drive belt is properly positioned within any belt guides or guards.

- Connect Spark Plug Wire: Reconnect the spark plug wire.

- Lower the Deck: Lower the mower deck to your desired cutting height.

- Test Drive: Start the mower and take it for a short test drive to ensure that the drive belt is functioning correctly. Listen for any unusual noises or vibrations.

- Final Adjustments: If necessary, make minor adjustments to the belt tension to ensure optimal performance.

By following these steps carefully, you can successfully install the drive belt on your Craftsman LT2000 riding lawn mower, ensuring it operates smoothly and efficiently.

FAQ

What Is the Craftsman Lt2000 Drive Belt Size?

The Craftsman LT2000 drive belt size is 1/2 x 95.5 inches. This is the size you will need to properly install the drive belt on your craftsman lt2000. Be sure to measure your current belt before ordering a new one to ensure you get the right size. Having the wrong size can lead to installation problems and decreased performance from your lawn tractor.

How Long Is the Drive Belt on A Craftsman Riding Mower?

The drive belt on a craftsman riding mower can be anywhere from 42 to 50 inches long, depending on the model. The primary belt is usually shorter than the secondary belt, and both belts are typically made of durable rubber or plastic.

If either of your belts fails, it’s important to replace them both at the same time to ensure optimal performance. You can find replacement belts at most home improvement stores or online.

Can You Adjust the Drive Belt on A Craftsman Lawn Mower?

No, then there s no need for adjustments. The manufacturer instead recommends simply replacing the belt if it becomes worn or damaged. It is not possible to adjust the blade drive belt on these machines.

Why Does My Drive Belt Keep Coming Off My Riding Mower?

There can be many reasons why a drive belt comes off a riding mower. However, in common scenes, it is due to the bearings of pulley or spindle housings, belt keepers, and brackets. If these components are not functioning properly, it can cause the belt to slip off. It is important to inspect these parts regularly and maintain them so that they are in good condition.

How Long Should a Mower Drive Belt Last?

Mower drive belts typically last between 3 and 4 years with regular use. However, this lifespan can be shortened if the belt is subjected to wet conditions or heavy loads. Additionally, if the belt is not properly tensioned it can wear out more quickly.

Warping Up

The craftsman LT2000 drive belt diagram is an illustration of the parts and their functions in the drive belt system. The diagram includes a list of the parts and their corresponding numbers, as well as a description of each part’s function. The diagram also includes a demonstration of the whole mechanism, as well as answers to the most commonly asked questions about the drive belt system.

We hope its contents were comprehensive in a manner to offer complete guidance on the problem you were looking for. If not, then seek professional assistance and offer them the whole picture leftover from the specific challenge you wish them to address.

Perhaps the issue is more complicated than it appears. And you should never delay in getting the repair done that your machine requires.

Catch you later on with another one!

Related Posts: